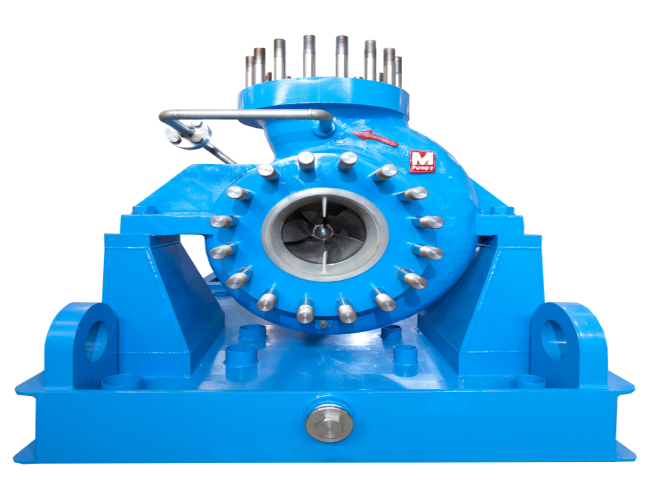

Centrifugal Pumps

State of the art centrifugal pumps from the simplest to the most demanding industrial process

application. Suitable for transfer, unloading, circulation and many other applications. High

efficiency, long life and low cost maintenance. Meeting several international standards (ISO/

DIN/ANSI/API) and available in both magnetic drive (sealless) and traditional mechanical seal.

•Flow up to 4000 m3/h

• Head up to 2200 m

• System pressure from vacuum up to 1500 bar

• Temperature from -150°C up to +400°C

• No heat exchanger required up to +350°C

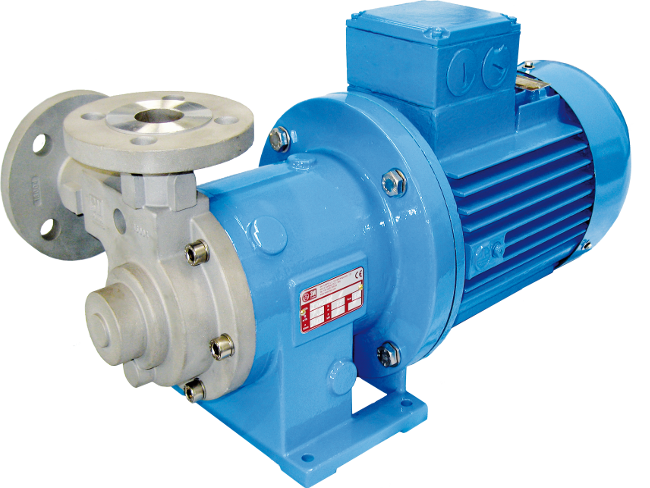

Regenerative Turbine Pumps

Low to medium flows, pulsation free, suitable where high pressure is required. Perfect solution

where traditional centrifugal pumps are not suitable (used instead of a multistage pumps).

Flow up to 24 m3/h

• Head up to 800 m

• System pressure from vacuum up to 1500 bar

• Temperature from -150°C up to +400°C

• No heat exchanger required up to +350°C

Side Channel Pumps

316 stainless steel (or better) multi-stage barrel construction. Ideal to pump liquefied gasses

and liquids under vapor pressure like condensate, refrigerant, boiler feed water or LPG (up to

50% gas content).

•From low to medium flows Best choice for truck unloading and natural gas handling.

• Low NPSHr 0,5 m.

• Self priming up to 5 m.

• Flow up to 40 m3/h

• Delivery Head up to 450 m

• System pressure up 50 bar

• Temperature from -90°C up to +250°C

Volumetric Pumps

SLIDING VANE PUMPS

• Flow rates up to 3000 l/h, discharge pressure up to 48 bar g.

• Suitable for viscosities from 1 to 1000 cP

• Pulsation free dosing/sampling/transfer pumps

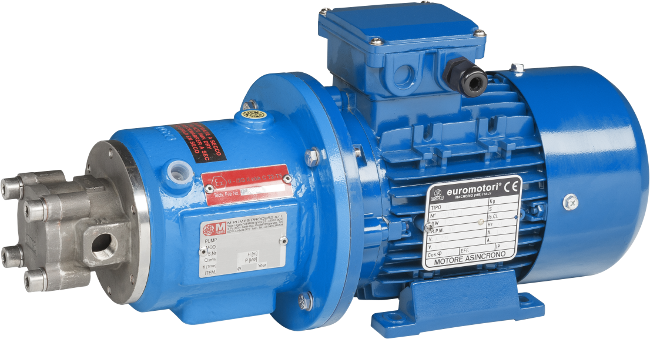

EXTERNAL GEAR PUMPS

• Flow rates up to 80 m3/h, discharge pressure up to 30 bar g.

• Suitable for lubricating media up to 25000 cP

• Temperature up to +200°C

HOLLOW DISC

• Flow rates up to 38 m3/h, discharge pressure up to 5 bar g

• Viscosities up to 10000 cP

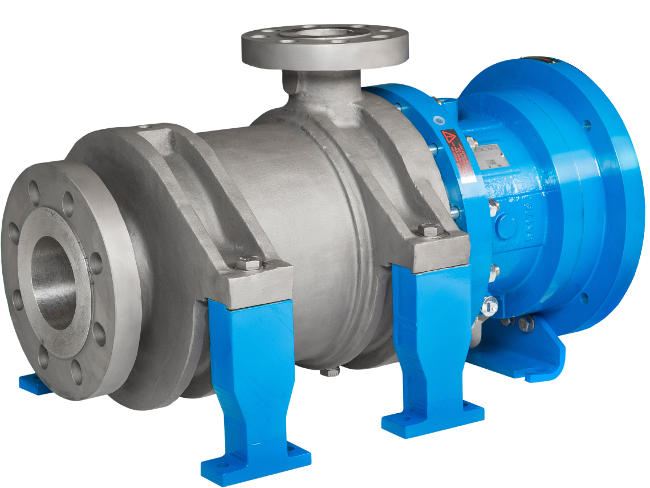

Special Pumps

M PUMPS is able to design and manufacture bespoke pumps for the most demanding

applications:

High system pressure

(up to 1500 bar g)

• High design temperature (400°C)

• Low design temperature (liquid CO2 cryogenic application)

• Solid content

• Jacketing

• Exotic materials such as: Hastelloy C® 276, Titanium, Monel®